Outsource Steel Joist Detailing and Design Services – Steel Joist Detailing and Design Services – Global Detailing and Designing

Steel joists and joist girders are the epitome of practical and economical framing solutions, offering unparalleled efficiency in supporting floors and roofs across a wide range of building applications. Meticulously designed and fabricated in strict adherence to the rigorous standards set forth by the esteemed Steel Joist Institute (SJI), these structural marvels embody the unwavering commitment to consistency, reliability, and above all, safety – the cornerstones of any successful construction project.

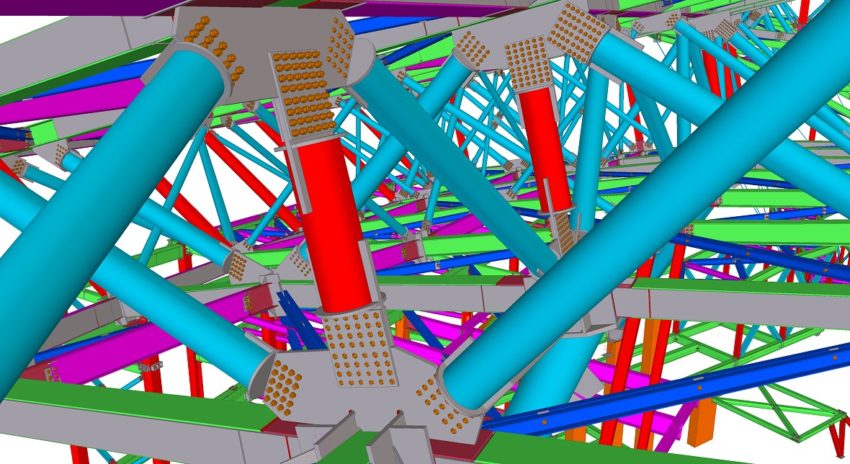

Engineered with precision and crafted with the utmost care, steel joists and joist girders stand as a testament to the enduring strength and durability of steel, a material that has withstood the test of time. Their sleek profiles belie the sheer might they wield, effortlessly bearing the weight of floors and roofs while maintaining an elegant and streamlined aesthetic. Moreover, the inherent versatility of these framing solutions allows for seamless integration into a diverse array of building designs, from sprawling commercial complexes to cozy residential dwellings.

With their unparalleled load-bearing capabilities and efficient spanning potential, steel joists and joist girders open up a world of possibilities for architects and engineers, enabling them to push the boundaries of structural ingenuity while ensuring optimal resource utilization.

Ultimately, the decision to incorporate steel joists and joist girders into a construction project is a resounding affirmation of the unwavering pursuit of quality, cost-effectiveness, and adherence to industry best practices. By embracing these time-tested framing solutions, builders and developers alike can confidently embark on their endeavors, secure in the knowledge that the structural integrity of their creations will stand the test of time, sheltering generations to come.

By adhering to the rigorous guidelines outlined in the SJI standard specifications, as mandated by widely adopted building codes like the International Building Code (IBC), engineers and architects can specify steel joists and joist girders with unwavering confidence. These meticulously crafted standards, forged through decades of research, testing, and industry collaboration, ensure that the specified components meet the most stringent load-bearing requirements and performance criteria. Compliance with these established norms is not merely a formality; it is a solemn commitment to structural integrity, functionality, and unwavering safety.

Each specification, each calculation, and each material requirement has been painstakingly scrutinized, leaving no room for uncertainty or compromise. By embracing these industry-leading standards, professionals in the field of construction are imbuing their projects with an unassailable foundation, one that can withstand the relentless forces of nature and the unforgiving test of time.

This steadfast adherence to the SJI standard specifications is more than just a box to check; it is a testament to the unwavering pursuit of excellence that defines the architectural and engineering professions. By following these guidelines, professionals are ensuring that their creations are not merely structures, but enduring monuments to human ingenuity and resilience, fortresses that will stand tall for generations to come.

A joist detailer plays a crucial role in the construction industry, meticulously crafting joist placement plans that serve as the blueprint for efficient and safe erection processes, much like a steel detailer’s intricate steel erection plans. At SCS, we understand the paramount importance of precision and expediency in this highly competitive market.

That’s why we offer comprehensive joist detailing services that not only increase the prospects of our esteemed clients but also deliver them with unparalleled speed and agility. Our offerings are tailored to meet the unique needs of each project, ensuring seamless integration and optimal performance.

From intricate load calculations and structural analysis to detailed joist layouts and connection designs, our team of seasoned professionals leaves no stone unturned in their pursuit of excellence.

- Open Web Steel Joists K-Series

- DLH-Series and LH-Series

- Deep Longspan and Longspan Steel Joists

- Single, Double, Parallel, One Way and Two Way Pitched Cords

We leverage cutting-edge technologies and industry best practices to streamline the detailing process, minimizing errors and maximizing efficiency. What truly sets us apart, however, is our unwavering commitment to quality and customer satisfaction. We understand that every project is a reflection of our clients’ reputation, and we take immense pride in delivering work that exceeds expectations.

Which Industry Standards & Codes we follow for Steel Modelling?

- NISD – National Institute of Steel Detailing

- AISC – American Institute of Steel Construction

- ANSI – American National Standards Institute

- OSHA – Occupational Safety and Health Administration

- RSIO – Reinforcing Steel Institute of Canada

- AS – Australian Standards

- BS – British Standards

- NZS – New Zealand Standards

- SABS – South African Detailing Standards

- SDI – Steel Deck Institute

- DIN – German Institute for Standardization

Project Buildings we implement our Service on?

- Modular Structures

- Industrial Buildings

- Commercial Buildings

- Institutional Buildings

- Residential Buildings

- Warehouse structures

- Hospital Structures

- Stadium

- Airport Structures

- Towers

- Parking Spaces

- Bridges

Our attention to detail, coupled with our ability to adapt to changing requirements, ensures that our clients can confidently tackle even the most complex projects, secure in the knowledge that their joist detailing needs are in capable hands.

While the standard load tables have traditionally presented allowable strengths as uniform loads, the reality is that the application of load in the completed project seldom adheres to this idealized scenario with precise uniformity. The distribution of loads in real-world structures is often far more complex and variable, deviating from the simplistic assumptions underlying these tables. This discrepancy between theoretical models and practical realities underscores the importance of recognizing the limitations of such standardized guidelines and the need for a more nuanced approach that accounts for the intricacies of each unique project.

The assumption of uniform loading is a convenient abstraction that facilitates the creation of generalized load tables, but it fails to capture the intricate interplay of forces and stresses that manifest in actual constructions. From localized stress concentrations to dynamic load fluctuations, the loading patterns encountered in the field can diverge significantly from the idealized scenarios envisioned in these tables.

Consequently, blindly relying on these oversimplified guidelines without considering the specific context and conditions of a project can potentially compromise structural integrity and safety. To address this challenge, a more comprehensive and tailored approach is essential. By leveraging advanced computational tools, finite element analysis, and rigorous site-specific assessments, engineers can develop more accurate models that account for the unique load distributions and complexities inherent in each project. This data-driven approach, combined with expert judgment and experience, can provide a more realistic representation of the loading scenarios and enable more informed decision-making, ensuring that structures are designed and constructed to withstand the actual loads they will encounter throughout their lifespan.

Joist manufacturers have embraced a strategic approach to optimize their products, recognizing the potential for significant cost savings. By meticulously designing joists to meet the precise uniform load requirements of each project, they can eliminate unnecessary overengineering and material waste. This innovative mindset allows manufacturers to create joists with tailored properties that fall between the standardized sizes and weights dictated by traditional SJI designations.

The result is a win-win scenario: clients benefit from joists that are custom-fitted to their specific needs, neither over-designed nor under-designed, while manufacturers can streamline their production processes and minimize material consumption. This level of precision not only translates into cost savings but also promotes sustainability by reducing the environmental impact associated with excess material usage.

This approach demonstrates the industry’s commitment to continuous improvement and innovation. By challenging conventional practices and embracing a more flexible, project-specific design philosophy, joist manufacturers are leading the way in delivering high-quality, cost-effective solutions that meet the evolving demands of the construction industry. This level of responsiveness and adaptability is crucial in an increasingly competitive market, where clients demand value, efficiency, and sustainable practices.