Outsource Material Handling Equipment Design Services – Bulk Material Handling Conveyors Design Services – Design and Analysis of Material Handling System

Material Handling Equipment Design Services are required to design the handling equipment for a given system. They are responsible for the complete design process, from conception to prototype development and finally production. The duties of this engineer include the layout and design of a material handling system, determining the correct chain and guide components, developing a detailed fabrication drawing of the equipment, ensuring that safety requirements are followed by all personnel involved in the project.

The material handling equipment designers need to know the various types of equipment that they can use in order to make the best choice. They also need to know about all the different kinds of materials that they will be handling as well as their properties. Material Handling Equipment Design Services are also responsible for creating drawings, which include technical drawings and sketches which will help them visualize how their design will work in practice. Most of the material handling equipment designers that work in the field are employed by large companies or organizations, with a few being self-employed. This career path can be found in manufacturing plants, warehouses, offices and other facilities. Material Handling Equipment Design Services position themselves as industrial designers. A material handling equipment designer creates drawings, which include technical drawings and sketches which will help them visualize how their design will work in practice. They create designs for engineering firms and other design companies. Most of the material handling equipment designers that work in the field are employed by large companies or organizations, with a few being self-employed.

Material handling equipment designers should have a good understanding of the wide range of engineering principles which are applied to design their products. They must know how to use CAD software and be familiar with industry standards and regulations regarding the safety, manufacturing, in-service inspection, and maintenance of their designs. Material handling equipment designers draft plans for companies or organizations that design large pieces. of equipment, such as excavators, trucks, aircrafts and cranes. They also draft plans for specific projects such as the design of a new building or manufacturing facility. Material handling equipment designers need to have good communication skills in order to be able to work with people from different backgrounds and come up with assignments for those people to do. Material handling equipment designers are also required.

Our Bulk Material Handling Engineering Design and Drafting Services:

Ø Cost Estimation & Preparing Technical offer for bulk material handling Equipment for Thermal Power plant, Steel & cement plant.

Ø Preparing & checking General arrangement drawings for Bulk Material handling Equipment, Such as Conveyors, tripper conveyor, Bucket Wheel Stacker-Cum-Reclaimer, Linear & Circular Stacker, Bridge & Portal Reclaimer, Bucket Elevator, Cranes, Crane shed, Apron Feeder, other Equipment drawings.

Ø Drawing Checking & relies for Manufacturing and Provide support for manufacturing.

Ø Plant & equipment layout design as per the customer tender document from conceptual to Detail engineering phase.

Ø Design and calculation of Belt Tension, Power calculation, Stability Calculation, Luffing Mechanism, Boom conveyor Drive, Stacking & Reclaiming capacity, Bucket Wheel Drive, Bucket sizing, Long Travel Drive, Slew Drive, Bucket Elevator, Cranes, Crane shed etc.

Ø Equipment sizing & selection such as Belt Rating, Drive Motor, Gear Box, coupling, Brake, Idlers, Pulleys, CRD, Magnetic separators, Belt Weather, Belt Cleaners, Hydraulic cylinders, Dust suppression system etc.

Ø Review vendor drawing & Technical specification for selection & approval of all bought out item like Gear box, Motor, Coupling, Brake, Belt, Bearing, Plummer block & Hydraulic cylinder.

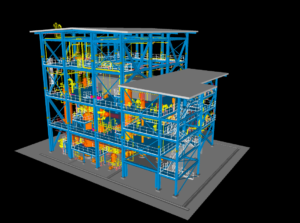

Ø Design & preparing 3D model, assembly models & Detail fabrication drawing using AutoCAD, Unigraphics.

Ø Responsible for managing detailing of all Steel Structural fabrications and manufacturing drawings of cement plants. Thermal Power Plants. Steel plant etc.

Ø Preparation of the appropriate STAAD model and Analysis based on Equipment load data and consideration of DL,LL,WL and stipulations as per Indian/International Codes.

Types Of Bulk Material Handling Engineering Global Detailing and Designing Perform.

Transfer Tower, Crusher House / Tower, Two Pole Trestle, Four Pole Trestle, Gallery / Gantry, Take-up tower

Engineering services for Structures

- Structural design (Member sizing)

- Structural GA drawing

- Connection design

- Shop fabrication drawing (3D & 2D)

Transport

- Loading & Unloading

- Long Distance Transport

- Ash Handling

- Raw Material Handling

Storage

- Silo Storage

- Stacking & Reclaiming

- Indoor / Outdoor Storage

- Pile Storage

- Dome Storage

- Tripper Conveying

Engineering services for CAPEX project Perform by Global Detailing and Designing:

Mechanical

- Belt conveyor design

- Conveyor layout & GA

- Detailed fabrication drawings

- Erection drawings

Electrical & Instrumentation

- Single line diagram

- Cable routing

- Cable & drum schedule

- Earthing & lightning protection

- Instrument layout diagram

- Junction box design

- Hook-up drawings

Civil & Structure

- Steel structure design

- RCC design

- GA drawing

- Foundation design

Process & Piping

- P&ID preparation

- Pipe routing

- Spool drawings

- Pipe stress analysis

Material Handling

- Tripper

- Crushing & Screening

- Stacker & Reclaimer

- Wagon Tippler

Mining

- Continuous Miner

- Flexible Conveying

- Mining Dredge

- Underground Equipment

- Longwall Shearer

- Truck mounted Oil Rigs

Port

- Port Cranes (STS, Goliath, RTGS)

- Ship Loader

- Ship Unloader

- Storage Hopper

Concrete

- Concrete Batch Equipment

- Mixing Equipment