Steel Structural Detailing Process | Global Detailing and Designing Steel Structural Detailing Services

Steel detailing is a very important step in the construction process. It is the process of preparing and documenting the structural steel for construction., and includes such activities as layout, punching, rolling, inspections and markings. This unique process is often considered a special skill that only steel fabricators can perform. The following steps are involved in the topic of detailing: Punching refers to the process of punching a series of holes along one or more sides of a piece of steel. Punching is performed by using various tools for piercing, cutting, and shearing. This operation is performed in order to create detailed drawings. The punching process can also be used for riveting metal components together. Rolling refers to the process which uses metal-reinforced rubber rolls.

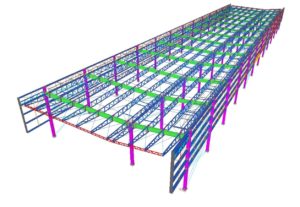

Steel detailing is a very important step in the construction process. It is the process of preparing and documenting the structural steel for construction, which includes all of its dimensions, materials, and connections. Steel detailing can be done manually or digitally with computer-aided design (CAD) software.

The main goals of steel detailing are to ensure safe construction, minimize construction costs, increase the structural integrity of the building, and optimize performance. This can be done both during project design and after construction is complete. Steel detailing is required in every US jurisdiction that has a building code. It also is a requirement for all large buildings under international codes such as The International Building Code (IBC) and The International Mechanical Code (IMC). Computer-aided design software programs such as Trigon, Abaqus, and SAP can be used for steel detailing. Steel detailing is a design process that takes into account the desired application and customer needs. It begins with understanding the material requirements for the project, including load paths and limits on building systems.

The steel detailing engineer then determines how much analysis to do in order to properly size structures and layouts. To complete this task, a steel-detailing software program is typically utilized along with computer-aided design software such as SketchUp and CAD. Steel detailing includes the following duties:

1) Pre-construction inspection. This is performed to ensure that the job site does not present any hazards or other issues that can hinder construction.

2) Structural analysis. This is done in order to calculate appropriate steel sizes for a given project, taking into account factors such as weight and stress loads. The structural engineer also performs calculations on a variety of angles in order to obtain optimal designs, which can also include calculating a “gross section moment of inertia” to determine the effect of a given design on the structure as a whole.

3) Steel detailing. This entails designing and producing cut sheets, plate sections, parts lists, and engineering drawings for each project’s components.

4) Installation/construction management. This includes coordinating installation with construction schedules and ensuring that safety guidelines are followed during construction by getting involved in any necessary meetings or communications with contractor representatives.

5) Engineering inspection. The steel- framed, metal clad building is one of the most fire-resistant structures available.

Steel detailing service might seem like a detail to overlook, but it is in fact crucial when it comes to building your structure. Before committing to any construction project, be sure you have a full understanding of steel detailing drawings & steel detailing standards.

The steel detailing services is one of the most important aspects of designing a steel building. Structural engineers and architects design buildings with the need to keep them safe, they also design them to meet certain standards and requirements. However, many designers are not aware that some of these practices can be achieved with the help of steel detailing drawings and steel detailing standards. The purpose of these drawings is to outline specific practices in order to make sure that all structural components work properly in concert with each other.

Steel detailing drawings outline the specific design practices, the steel detailing standards outline how these practices should be implemented. Designers need to pay attention to both of these documents in order to ensure that the buildings are safe and meet certain standards.

Steel detailing standards

A steel detailing professional should be aware of the specific requirements for the construction and design industry in different countries, such as those specified by:

- American Institute of Steel Construction (AISC)

- American Welding Society (AWS)

- National Institute of Steel Detailing (NISD)

- Canadian Institute of Steel Construction

- Australian Institute of Steel Construction

- Euro Codes and British Standard Codes

Steel detailing involves the creation of detailed drawings for fabricators and contractors, and includes plans and estimates, as well as other reports and important tasks. The process involves two main types of drawings—shop drawings and erection drawings. A shop drawing is the final, detailed drawing depicting the work to be performed by contractors. An erection drawing provides details of how a building or structure will be assembled after construction. Fabricators and contractors may create shop drawings as-built, or change them before construction begins. They may also use them for estimating purposes during request for proposal (RFP) competitions. An example of an as-built shop drawing would be a steel detailing plan with annotations and changes made at various stages during A construction company might create an as-built shop drawing to record changes made to the steel design during construction.

Steel fabricators are not efficient in the current supply chain system. A typical fabrication company spends a significant amount of time creating difficult-to-read drawings because of lack of standardization in drawing systems.

With Shop Drawings, you’ll be able to automatically generate drawings for even the most complicated steel components with ease. Steel fabricators will spend less time creating drawings and more time fabricating your high-quality steel pieces.

Design customized steel components for your specific project within minutes, with detailed drawings and specifications that are ready to be executed by the steel fabricator right away!

4 thoughts on “Steel Structural Detailing Process”